How To Scrape Heated Build Plate Clean

It happened to me when I got started in 3D printing, then it may equally well be happening to y'all. You think you lot found those aureate settings on your slicer that only output nice-looking prints and yous get the feeling that you lot may be a printing genius.

Perhaps, you lot remember, y'all should buy twenty more printers and start your own press farm. In your mind, you are already thinking about the size of your future yacht and its amenities.

Suddenly, your objects detach from the build plate in mid-print. It may be fourth dimension for a new series of tutorials earlier we can get dorsum to our 3D printing empire.

If what happened above is word for word what happened to you lot, it may exist time to learn how to keep a clean printer bed (and lower your overall expectations).

A clean printing bed is especially of import for improving layer adhesion to the build plate and yields a better looking offset layer. Isopropyl Booze (IPA) in graduations ranging from 70% up to 99.99% is advisable for this task.

Soak the IPA in paper towels, microfiber cloth, or cotton and clean the bed surface in a circular motility. Rinse and echo until the build plate is free of leftover filament, fingerprints, oils, and other imperfections that impact printing quality. Depending on the build plate type, y'all can also use acetone, but only utilise it as a terminal resort and on the specific parts where y'all could non clean it using alcohol.

If you do not know if your build plate is muddy or clean, assume that it needs some cleaning. Information technology never hurts!

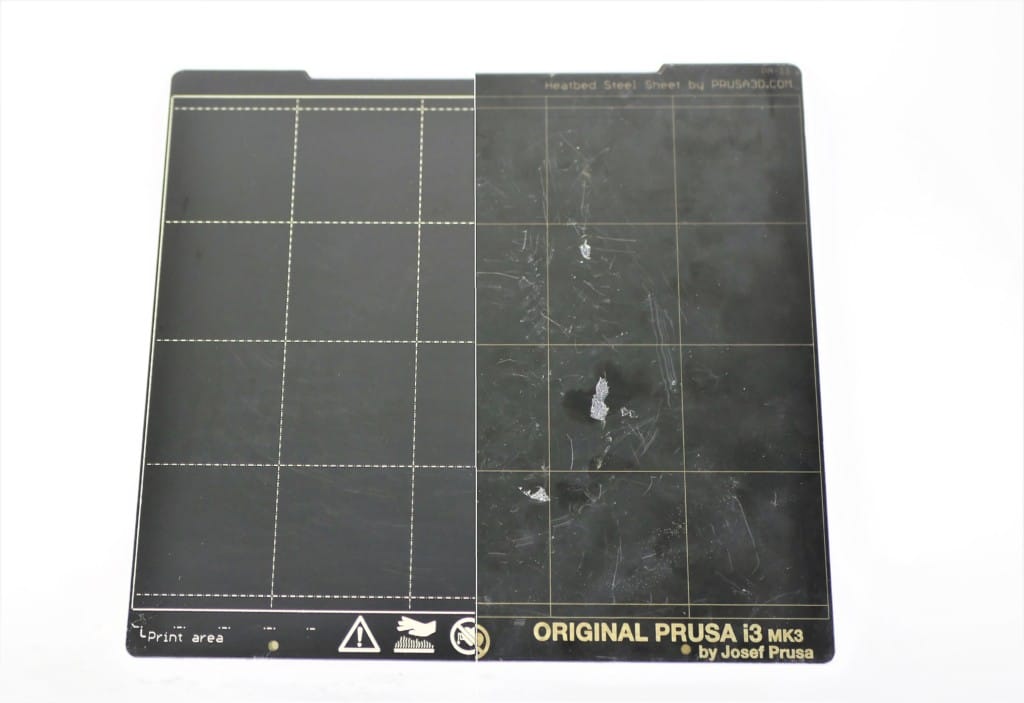

Look at the picture below. If your surface looks like the left-hand side, you clearly do non suffer from muddy-build-plate syndrome (or DBPS). On the other hand, if you identify with the correct side of the picture, it does not take a germaphobe (nor a tutorial) to infer that some cleaning may be necessary.

- Why is 3D Printer Bed Cleaning Of import?

- Advantages of a Make clean 3D Printer Bed

- Maintaining Your 3D Printing Bed

- Polyetherimide (PEI) Press Beds

- Glass

- Adhesive Tape

- Conclusion

Why is 3D Printer Bed Cleaning Important?

The 3D printer bed serves equally the base of operations on which your model is printed on. The printing process tin leave residual filament later on the process is completed.

The bed besides becomes dirty by general handling (skin oil, fingerprints, dirt, etc.) and materials from its surroundings. These contaminants bear on the quality of your future prints and damage the printing bed over time.

Skipping maintenance can ultimately crusade irreversible harm that tin can only be resolved by replacing the press bed.

Advantages of a Clean 3D Printer Bed

Having a make clean 3D printer bed is essential for achieving perfect results. Unclean beds take recurring issues with layer adhesion that compromise the quality of your prints.

Keeping the 3D printing bed in an acceptable state prolongs its serviceable life and can relieve you from spending a few extra bucks on somewhat expensive replacements.

A key issue with printing is the quality of the first layer and its adhesion to the build plate.

A make clean 3D printer bed ensures your models print properly without any bug. Remember to follow the recommended care for your press bed equally information technology varies according to models and their materials.

Maintaining Your 3D Press Bed

Well-nigh printer beds are fabricated of drinking glass Polyetherimide (besides known as PEI) or covered in tape. At 3DSolved we leave (most) no rock unturned, then we will cover those types!

Polyetherimide (PEI) Printing Beds

PEI sheets are existence actively used as 3D printer bedding since they require little maintenance and are suitable for the process. They are also resistant to wear under extreme temperature and radiation that are a regular feature in 3D printing.

PEI sheets have good bed adhesion and don't normally go stuck with the model if maintained properly. Consequently, there are few instances where adhesives and tapes are needed when using them.

Even so, PEI sheets practise demand maintenance to keep upwards the quality of their prints. Their adhesion becomes weaker over fourth dimension equally the bed is repeatedly subjected to printing radiation, temperatures, 3D press inks, environmental contaminants, and general handling.

This leaves glue, printing ink, and filaments every bit well as oils and dirt on the surface. Simple cleaning procedures such as scratching, scraping, and wiping with whatsoever cleaner can damage the bed.

How to clean a PEI Printing Bed

The following is the recommended way to clean a PEI 3D printing bed:

What You Need

You will need the following materials for cleaning the PEI 3D press bed:

- Isopropyl Alcohol (IPA) at 70% to 99.99% concentration (depends on cleaning)

- Acetone/Propanone

- Newspaper towels, microfiber cloth, or cotton fiber

- Sandpaper (+1,500 grit)

The Process

Using unscented IPA at ~70% concentration is a safe standard to make clean PEI 3D printing beds. It is volatile (information technology evaporates), which means you don't have to worry about a liquid mess. Higher purity of IPA can be used in cases where oils, dirt, and grease have been layered considerably.

As a safety precaution, exist sure to always employ it in a well-ventilated area.

Let the 3D printing bed absurd down before starting maintenance. Apply IPA and wipe it well with a dry out microfiber textile, paper towel, or cotton. The college concentration of IPA completely breaks down organic oils and makes them easier to remove.

Use acetone for removing 3D ink and plastics that are stubbornly bonded with the bed. Cascade the acetone on the fabric (not directly on the bed) to dampen information technology.

While PEI is non soluble in acetone, pouring also much on i area for prolonged periods can however damage it. Wipe the bed in round strokes to remove the plastic compounds. You may pour some of information technology directly on tough stains to soften them for removal.

Remember to apply acetone only when booze is no longer completely cleaning the surface.

In example of very stubborn stains or uneven surface, use fine-dust sandpaper (+i,500 grit) to scrub off the buildup or only smoothen the surface for fifty-fifty traction after cleaning it. Remember to clean once more as sandpapering produces very fine grit from grinding the surface.

Time for Maintenance

The fourth dimension between maintenance is variable for different brands of PEI sheets and how frequently they are used. It also decides their serviceable life. Using glue and hair spray has also become a common hack to prevent the model from sticking to the bed. While the technique has proven effective, cleaning up tin can go problematic without proper guidelines.

To avoid damage, follow the instructions, though wiping is a standard after a few prints. Depending on the usage (a calendar month on average), you may have to use acetone and sandpaper for restoration.

Glass

Glass is a very common material for 3D printing. It has a longer serviceable life than PEI. Information technology also facilitates the usage of hairspray and adhesives for the 3D printing process because the surface does not react with whatever material. Glass 3D printing beds take an even surface that is also relatively easy to clean.

Glass by itself does not accept a good surface adhesion. It is usually used with adhesives such as mucilage sticks and hairsprays. They increase surface adhesion for the first layer of impress that sets a stable base for the rest of the model.

Cleaning Glass 3D Printing Beds

The following is the recommended way to make clean a glass 3D press bed:

What You Demand

- Scraper

- Dishwashing soap

- Sponge

- Isopropyl Alcohol (IPA) at 70% to 99.99% concentration (depends on cleaning)

- Newspaper towels, microfiber cloth, or cotton fiber

The Process

Working with a heated drinking glass 3D press bed is easy as the surface does not get sensitive after getting warm. The heat makes the remainder materials easier to scrape off. Be careful when scraping as glass is prone to scratches from sharp objects.

For starters, you should remove whatsoever traces of glue and hairspray on your glass 3D printing bed. This can easily be done with smoothen, leveled objects such as a plastic ruler or metal spatula. Apply only the necessary force when using metal equally information technology can scratch the drinking glass. After removing gum, you can movement on to removing the press textile stuck from the bed.

The bract on a scraper is extremely precipitous. Exert a downward strength with one mitt and become a practiced grip at the edge or in the middle of the drinking glass bed with the other. This will help remove the leftover material properly and forbid your hand from slipping. Call back that you will have to make clean the bed later when yous touch it with your hands, as information technology will leave balance oils and dirt.

Soap and h2o are perfect for removing glue and hairspray. Check the composition of your product to find out its solubility in h2o. In some cases, acetone and alcohol are ameliorate solvents for removing them. Wipe with dispensable paper cloths or cotton because cleaning a microfiber cloth is difficult once used for this purpose.

Notation: Be conscientious when using liquids because they can damage the nearby electronic equipment.

Time for Maintenance

The time between maintenance of your 3D printing bed volition vary depending on the usage and materials used to print the models. Scraping later on every impress removes whatever printing material stuck to the bed and prevents buildup which becomes harder to clean. It also keeps the next model'south base clean and easy to detach.

Use soap and water every week if the bed is existence used every day. Otherwise, monthly maintenance is skillful enough to keep the prints well adhered. Use IPA and acetone merely when the buildup has get very tough to remove.

Adhesive Tape

Adhesive tape is easy to use and cheap to replace. This makes it a reliable choice for anyone getting into 3D printing or looking for a inexpensive yet reliable 3D printing bed. It is generally used with non-heated beds considering information technology is sensitive to heat. Masking and painter'south tape are among the meridian choices for making an adhesive tape 3D printing bed.

Cleaning Adhesive Tape 3D Press Bed

The following is the recommended way to clean an adhesive record 3D printing bed:

What You Need

- More tape of the same kind

- Scraper, plastic ruler, or metal spatula

- Isopropyl Alcohol (IPA) at 70% to 99.99% concentration (depends on cleaning)

- Dishwashing lather

- Sponge

- Paper towels, microfiber cloth, or cotton

The Process

While adhesive tape is like shooting fish in a barrel to use, it is equally hard to clean up. Scraping with a metal spatula is skillful enough to clean rest filament. Patch whatsoever area that is showing signs of clothing. Be conscientious to maintain the level of your 3D printing bed (link to Ender 3 bed leveling guide) to ensure the model is printed without defects.

At times your bed will either exist merely too used or volition non accept an fifty-fifty level. This is an indication to replace information technology. Remove all of the tapes and clean the base of the bed with IPA or soap and water. Let it dry completely, and and so utilize a fresh layer.

Fourth dimension for Maintenance

Agglutinative tape 3D press beds accept a short lifespan and demand to be repaired and replaced often. Lightly scrape the surface after every print and replace the entire record subsequently a week or biweekly ground, depending on the frequency of usage.

Conclusion

By now, you should take no excuse for having a dirty printing bed on your machine. I should mention that I am not the most methodic person in the 3D printing world, so I tend to clean it when I start to run into a higher failure rate. In short, my strategy tin can be described as reactive instead of preemptive.

If yous do not want to get frustrated from fourth dimension to time, waste filament, and get poor quality prints, you lot should always thrive to practice preemptive maintenance to your 3D printer, and a clean printing surface is certainly not the exception!

Source: https://3dsolved.com/how-to-clean-a-3d-printer-bed-the-correct-way/

Posted by: saxontiontems.blogspot.com

0 Response to "How To Scrape Heated Build Plate Clean"

Post a Comment